Startup

The First Month after the Workshop

-

This time has been about getting all the pieces put together.

I had started a ventilation upgrade before the workshop that, as these things

are wont to go, didn't quite get done until I got back. I used to

mix all my own brews, but in recent years I've gotten lazy - liquid concentrates

and less respect for my lungs than is smart. I unplugged the little

darkroom exhaust fan and put in hoods made by Edwards Engineered Products (http://eepjon.com/)

and a 300 cfm fan. And there was fresh air!

-

The only piece of critical equipment that I needed to buy was a

magnetic stirring hot plate. The new, digital models are outside my

budget, but I found a very good, used analog model on eBay. $145.

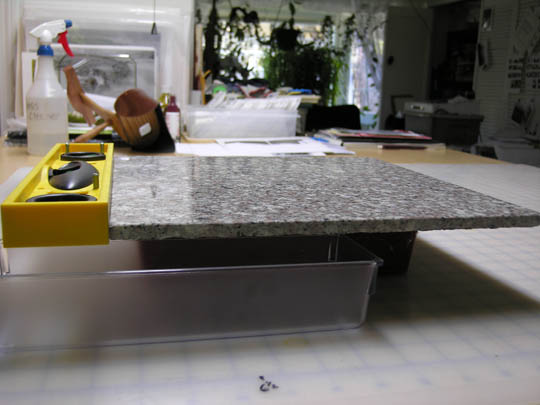

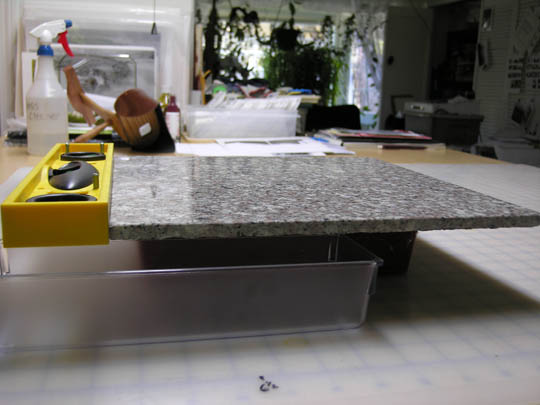

Front view of blade coating platform: Nylon cutting board with level attached

with bolts (removable), feet to raise it high enough for an emulsion overflow

catch tray to fit underneath. The warm granite is placed next to the level

right before coating. |

Bottom: Tray feet attached with screws around the rims and then heavily

sealed with silicone adhesive |

-

While I was waiting for my hot plate, I staged various

workflows. I know myself. If it's too complicated to take up and

down, I'll gradually find excuses to do anything else. (a darkroom

as big as a garage would be nice - the darkrooms at the Formulary could spoil

a person).

From left: magnetic stirring hot plate and tempering unit set on removable

countertop set over sink, emulsion coating platform,

rack for holding granite and coated sheets until emulsion sets, and under that,

stacked screens for drying paper. |

|

Chemical weighing station. |

|

Granite tiles and buffet warming unit to keep stones at coating temperature. |

|

-

There were misc. calibrations and calculations and, above all, ordering my

workshop notes into something useable. I plan to start with 4 x 6+ inch

size negatives (digital negs from 120 film, made with a Nikon ED 9000 and Epson

2400 printer on Pictorico OHP).

July 21 and 22, 2006 / Lot 1a

Made 1x scale emulsion recipe and did one set (i.e. 1/4 total)

of coatings: Straight from the class notes, with 1 drop surfactant and

6 drops hardener per 50 ml melt. A 4 x 5 coating blade calibrated to 6 mil.

I coated baryta paper (1), Rives BFK-white (2), Fabriano Artisto-x white

(2), Arches Platine (1), and Crane's Cover 90 (2). Total 7 sheets, coated

5 x 8 inches. I started with my standard developer, ZonalPro HQ

(chosen because to doesn't contain Metol (I have become sensitive), very dilute

acetic acid stop bath, and plain hypo fixer.

Results: The Crane's fell apart. It's out of the running.

The Rives and Platine are too rough for my taste (? try them later with a

gelatin first coat ?)

Surfactant problem, do you think?

Baryta paper. The worst cratering, but all the papers were affected. |

|

Magnified crop:

'peppering' as well as craters

The good news: the

image between the craters and pepper grains is really quite pretty. |

|

July 24 and 25, 2006 / Lot 1b

Changes:

-

Increased prime hardener to 7 drops.

-

changed prime surfactant to 2 drops Photo Flo 600.

-

Preheated granite in 200 degree oven, and kept it warm wrapped

in a baby quilt.

-

strained silvered gel through filter before adding to the 10% gel.

Papers: Arches HP, Fabriano Artistico, baryta, and

gelatin-sized Somerset Satin (my favorite surface for albumen printing)

Results:

-

Significant reduction in cratering.

-

Peppering reduced, but still unacceptable.

-

There might have been an increase in speed and grain size from

last time (when I made the coating melt from freshly prepared gel, rather than

re-melting gel that had been refrigerated.???)

-

The Somerset results were too grotesque to publish on the

internet, but worth pursuing. The emulsion that was evenly laid down has

a "depth" that the other coatings lack.

-

The Arches HP evenly mottled in the developer - the whole

sheet, not just the coated area This disappeared when the paper

dried, but it's out of the running for now.

Fabriano Artistico: I felt the coating blade grab as I

started. The paper fibers give the print the appearance of graininess

(like a too-big enlargement from 35mm TriX, but with the detail of a larger

format negative) ?artsy avenue? |

|

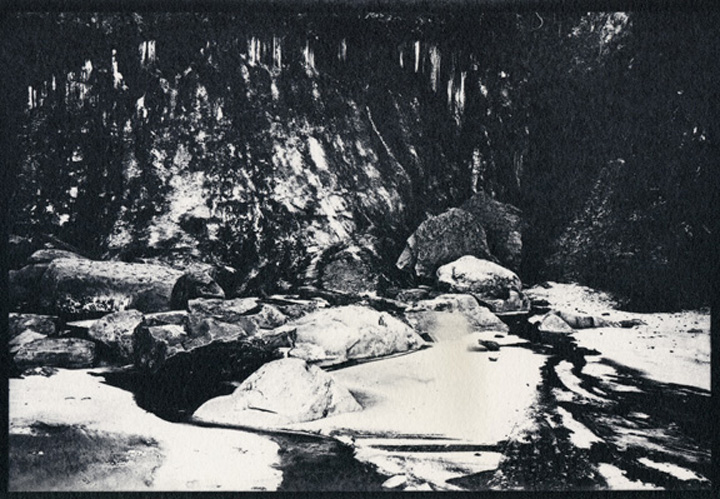

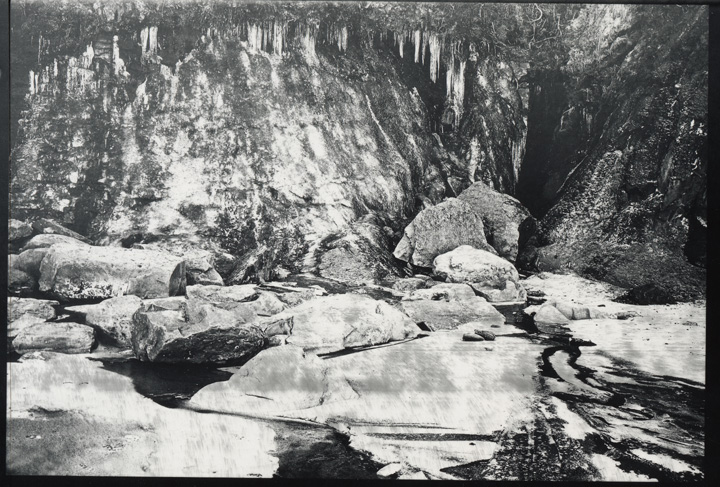

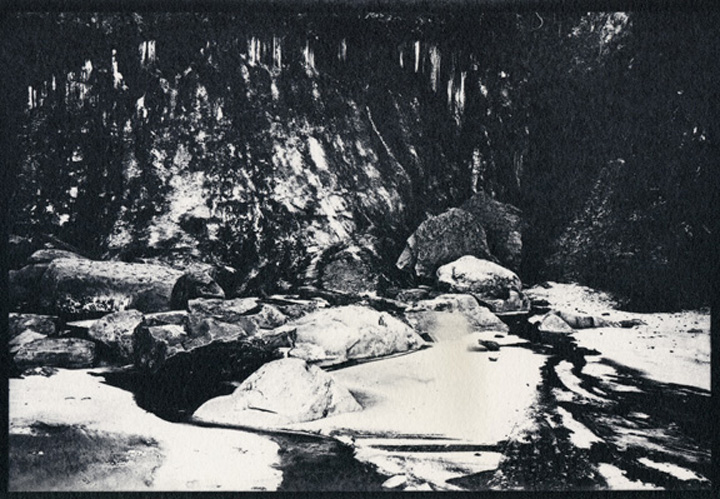

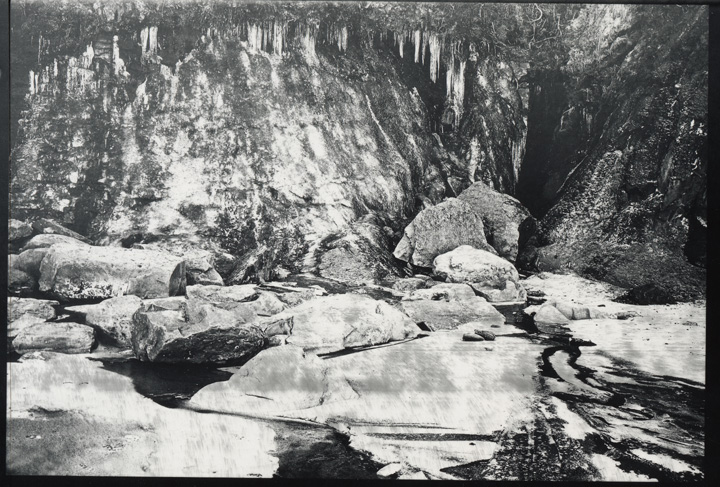

Baryta: I hadn't realized I was down to the dregs

and bubbles of the emulsion. I decided to go ahead anyway. Where it

coated well, it compares favorably with commercial paper. Needless to say,

the devil lives in "Coated Well". |

|

Closeup detail of the above print. |

|

July 30 - August 1, 2006 / Lots 1C and 1D

Lot 1C: Granite too hot (amazing how fast baryta paper can curl!)

Packed it in for some medicinal chocolate.

Lot 1D:

Changes: PhotoFlo 600: 6 drops. Change developer to ZonalPro

FactorOne (recommended dilution).

Papers: Baryta and Fabriano

Results: Surfactant problems resolved on Fabriano paper. No

craters. Almost perfect on baryta.

It's paper fork-in-the-road time. The Fabriano and baryta handle

differently and will need separate negatives with different characteristics.

The Fabriano paper looks like it has a much steeper curve with little

shoulder or toe. (Obviously, that's a first read.) It is

much more forgiving of emulsion defects, and the overall look is very

appealing, so I will come back to it after pursuing baryta for awhile.

Baryta: It looks like the pepper grains are changing over time

(?softening?) They didn't show on the Fabriano paper and on the baryta

they look like a smear rather than flecks.

Additionally, before I continue I will have to figure out how to keep the

granite at a consistent temperature. I tried a heating pad, but its

safety controls override the necessities of this job.

Fabriano |

|

| |

Baryta |

|

| |

500% detail of above print, showing smeared silver grains |

|

| |

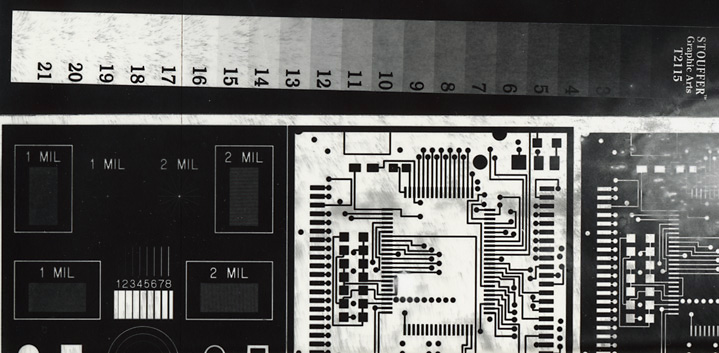

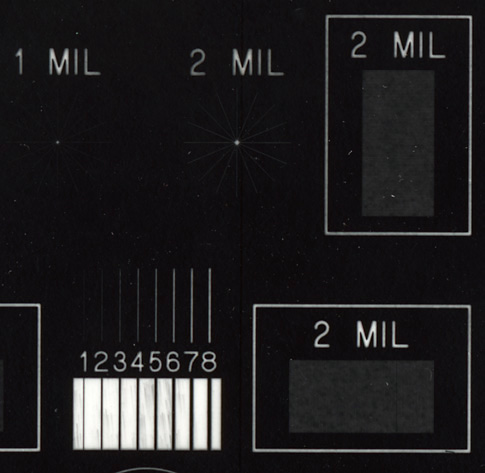

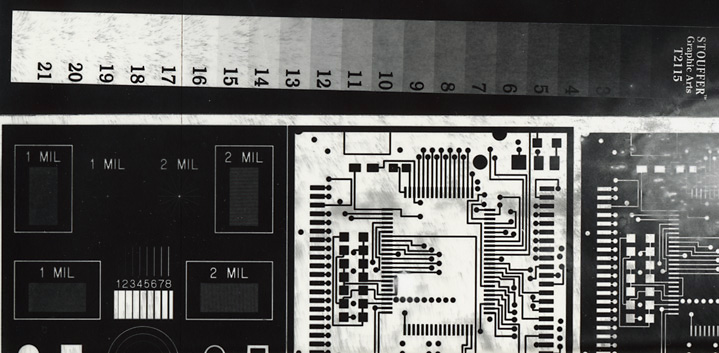

Baryta: Step tablet and resolution target at 200% |

|

| |

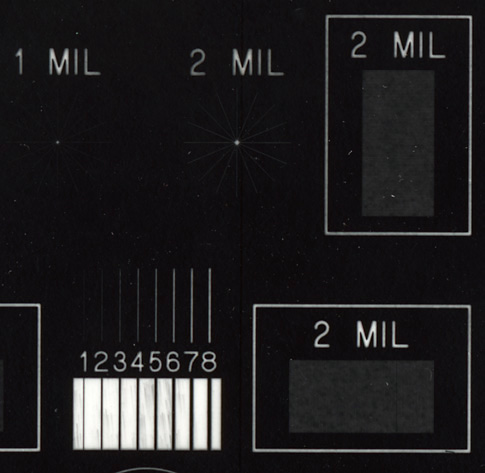

500% detail of above print |

|

Denise W Ross Photography